Enhanced TDS

Identification & Functionality

- Pigment Type

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Ink & Toner End Applications

Properties

- Color (Properties)

- Physical Form

- Appearance

- Free flowing crystalline powder

- Odor

- Odorless

- Insoluble in

- Water, Organic solvents

- Physical Properties

Value Units Test Method / Conditions Visible Color (at 0°) Gold - - Visible Color (at 120°) Yellow-green - - Melting Point min. 400 °C - Particle Size (D₉₀V) max. 25 μm -

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Observation Method

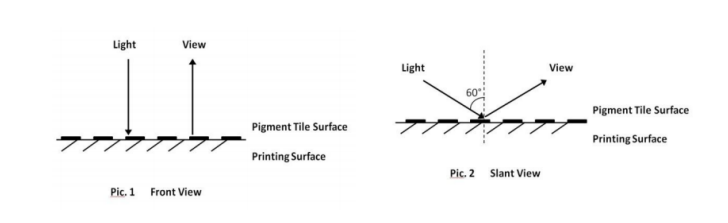

To observe the full range of the color shifting effect, the OVP is made into an Optically Variable Ink that is printed onto a suitable material. The viewing angle at 0° means both the observer and the light source are aimed directly at the printed surface. The viewing angle at 120° means the light source is positioned at 60° to the surface and the observer is at 60° to the printed surface, opposite of the light source (120° total), as indicated below:

Observation Method

a) Front view

The angle between the normal to the flat where the pigment lays and the light and the angle between that and the observing angle are both 0 degree. (See Picture. 1)

b) Slant view

The angle between the normal to the flat where the pigment lays and the light and the angle between that and the observing angle are both 60 degree. (See Picture. 2)